|

• LMR® standard is a UV Resistant Polyethylene jacketed cable designed for 20-year service outdoor use. The bending and handling characteristics are significantly better than air-dielectric and corrugated hard-line cables.

• LMR®- DB is identical to standard LMR plus has the advantage of being watertight. The addition of waterproofing compound in and around the foil/braid insures continuous reliable service should the jacket be inadvertently damaged during installation or in the future.

• LMR®- FR is a non-halogen (non-toxic), low smoke, fire retardant cable designed for in-building runs that can be routed anywhere except air handling plenums. LMR-FR is UL/NEC & CSA rated‘CMR’ and ‘FT4’ respectively, meets FAA FAR25 requirements and is MSHA-P for mining applications.

• LMR®- FR-PVC is a general-purpose indoor cable and has a UL/NEC & CSA rating of ‘CMR’ and ‘FT4’ respectively. It is less expensive than LMR-FR, however it emits toxic fumes (HCL) and greater smoke density when burned.

• LMR®- PVC is designed for low loss general-purpose applications and is somewhat more flexible than the standard polyethylene jacketed LMR.

• LMR®- PVC-W is a white-jacketed version of LMRPVC for marine and other applications where color compatibility is desired.

• Flexibility and bendability are hallmarks of the LMR- 600 cable design. The flexible outer conductor enables the tightest bend radius available for any cable of similar size and performance.

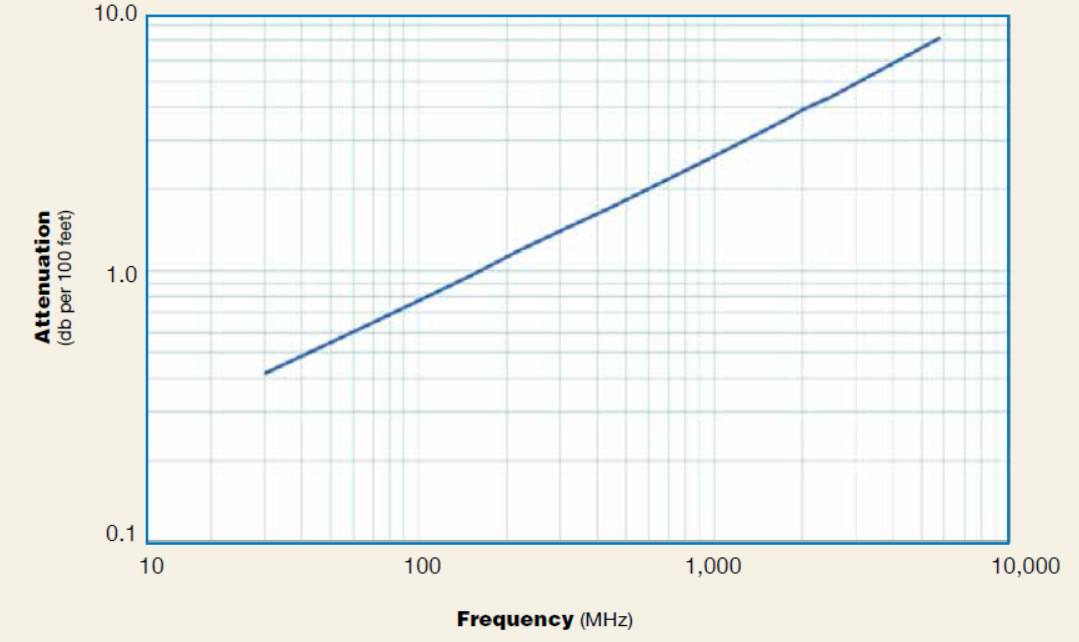

• Low Loss is another hallmark feature of LMR-600.Size for size LMR has the lowest loss of any flexible cable and comparable loss to semirigid hard-line cables.

|

• RF Shielding is 50 dB greater than typical single shielded coax (40 dB). The multi-ply bonded foil outer conductor is rated conservatively at > 90 dB (i.e. >180 dB between two adjacent cables).

• Weatherability: LMR-600 cables designed for outdoor exposure incorporate the best materials for UV resistance and have life expectancy in excess of 20 years.

• Connectors: A wide variety of connectors are available for LMR-600 cable, including all common interface types, reverse polarity, and a choice of solder or non-solder center pins. Most LMR connectors employ crimp outer attachment using standard hex crimp sizes.

• Cable Assemblies: All LMR-600 cable types are available as pre-terminated cable assemblies. Refer to the section on FlexTech for further details.

| Part Description |

Stock |

| Part Number |

Application |

Jacket |

Color |

Code |

| LMR-600 |

Outdoor |

PE |

Black |

54003 |

| LMR-600-DB |

Outdoor/Watertight |

PE |

Black |

54093 |

| LMR-600-FR |

Indoor/Outdoor Riser CMR |

FRPE |

Black |

54032 |

| LMR-600-FR-PVC |

Indoor/Outdoor Riser CMR |

FRPVC |

Black |

54074 |

| LMR-600-PVC |

General Purpose |

PVC |

Black |

54219 |

| LMR-600-PVC-W |

General Purpose |

PVC |

White |

54206 |

| Construction Specifications |

| Description |

Material |

In. |

(mm) |

| Inner Conductor |

Solid BCCAl |

0.176 |

(4.47) |

| Dielectric |

Foam PE |

0.455 |

(11.56) |

| Outer Conductor |

Aluminum Tape |

0.461 |

(11.71) |

| Overall Braid |

Tinned Copper |

0.490 |

(12.45) |

| Jacket |

(see table above) |

0.590 |

(14.99) |

|

| Mechanical Specifications |

| Performance Property |

Units |

US |

(metric) |

| Bend Radius: installation |

in. (mm) |

1.50 |

(38.1) |

| Bend Radius: repeated |

in. (mm) |

6.0 |

(152.4) |

| Bending Moment |

ft-lb (N-m) |

2.75 |

(3.73) |

| Weight |

lb/ft (kg/m) |

0.131 |

(0.20) |

| Tensile Strength |

lb (kg) |

350 |

158.9) |

| Flat Plate Crush |

lb/in. (kg/mm) |

60 |

(1.07) |

| En vironmental Specifications |

| Performance Property |

oF |

oC |

| Installation Temperature Range |

-40/+185 |

-40/+85 |

| Storage Temperature Range |

-94/+185 |

-70/+85 |

| Operating Temperature Range |

-40/+185 |

-40/+85 |

|

| Electrical Specifications |

| Performance Property |

Units |

US |

(metric) |

| Velocity of Propagation |

% |

87 |

|

| Dielectric Constant |

NA |

1.32 |

|

| Time Delay |

nS/ft (nS/m) |

1.17 |

(3.83) |

| Impedance |

ohms |

50 |

|

| Capacitance |

pF/ft (pF/m) |

23.4 |

(76.6) |

| Inductance |

uH/ft (uH/m) |

0.058 |

(0.19) |

| Shielding Effectiveness |

dB |

>90 |

|

| DC Resistance |

| Inner Conductor |

ohms/1000ft (/km) |

0.53 |

(1.7) |

| Outer Conductor |

ohms/1000ft (/km) |

1.2 |

(3.9) |

| Voltage Withstand |

Volts DC |

4000 |

|

| Jacket Spark |

Volts RMS |

8000 |

|

| Peak Power |

kW |

40 |

|

|